The wolf rovers build process

Twelve steps that result in an unparalleled legacy Land Rover Defender. Our Wolf Classics trucks are hand-built in Kingfield, Maine, and designed specifically for daily worry-free adventures right here in the United States.

start with a solid base.

Rather than sandblasting, cutting, patching, welding, and repainting, we start with a brand new OEM chassis sourced directly from Land Rover that is factory stamped with proper factory VIN.

strengthen your steel

All reused steel/cast exterior components such as link arms, trailing arms, steering arms, etc. are sand blasted back to white metal, acid-etched, epoxy primed, and industrial urethane coated with the same material used in the manufacture of today’s oil drums. This provides our clients with a high-quality, long-lasting finish and protective coating to ensure long-term rust resilience.

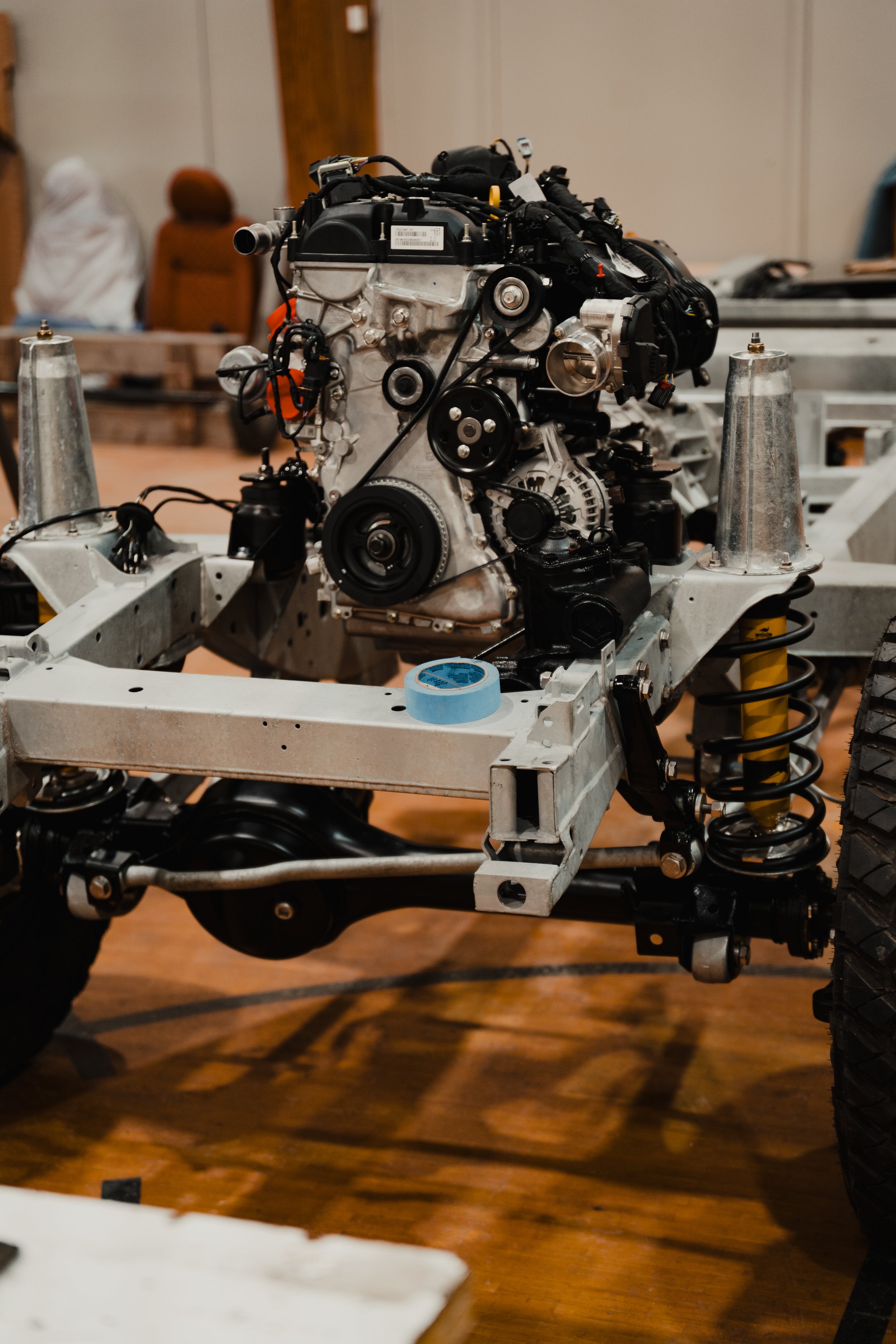

oem puma suspension

All new OEM steel and rubber bushings are pressed, and Land Rover’s most modern Defender suspension parts (known as Puma) are then paired with rebuilt axles and running gear to create a new rolling chassis. All secured by stainless or Grade 8 hardware.

modern Ford EcoBoost engine

After years of testing both on and off-road, our preferred engine of choice is the crate Ford EcoBoost engine. The Defender has a notorious rap in the marketplace as it relates to overall reliability issues. Most commonly engine related. The Ford Ecoboost engine is a perfect replacement engine for a classic Land Rover Defender due to its combination of power, efficiency, and reliability. The Ecoboost engine has a turbocharged direct-injection design, providing impressive power output and torque delivery. Additionally, the Ecoboost engine is fuel-efficient, which is a significant advantage for a vehicle that is primarily used for off-road adventures. The Ecoboost engine's reliability is also noteworthy, as it is built to withstand tough conditions and has been tested for durability. Overall, the Ford Ecoboost engine is an excellent option for those looking to upgrade their classic Land Rover Defender's performance while maintaining its classic charm.

manual or automatic transmision

When pairing a significantly more powerful engine, it is our opinion that a stronger transmission is required to get power consistently down to the wheels. We offer both manual and automatic transmissions dependent on driver preference. We see a disproportionate preference for the automatic solution.

Manual Transmission: Fully rebuilt Getrag MT82 6-speed manual with high-performance LOF clutch system. This was the OEM transmission for all Defenders built between 2007 and 2016.

Automatic: Ashcroft fully rebuilt ZF 4HP24 Rover spec automatic with custom programmed Compushift controller. This is an improved version of the automatic transmission supplied by Land Rover.

New Ford 10R80 10-Speed automatic transmission complete with 'Sport Mode' to provide an even more exhilarating driving experience.

heavy duty transfer case

To properly place the power down to the wheels, we utilize an OEM transfer case located in the original factory position and fully rebuilt by Dave Ashcroft with a 1.22 ratio. This LT230 transfer case is upgraded with HD bearings, drilled and pressed shaft guide, and HD cross pin for the ultimate in durability and performance.

high performance brake system

A commonly overlooked system when builders swap for larger power plants is getting the trucks to stop appropriately. It is our opinion that when increasing both the horsepower and torque of the drivetrain, you need something equally capable of bringing the truck back down from orbit. We use all brand-new stainless-steel factory pre-bent piping and OEM performance NAS spec rotors with LOF high-performance pads. A full LOF oversized Multi piston braking systems are available to further increase overall performance.

air conditioning and cooling

With all of the aforementioned drivetrain improvements, passenger comfort has been additionally addressed.

The land Rover Legacy Defender is first and foremost a true utility vehicle. Passenger comfort may never have been on the list of deliverables for the designs. If you’ve driven/ridden in one of these vehicles before, you’ve likely experienced the overwhelming heat in the summer even with an AC system on full and the ‘never really warm’ cabin climate in the cooler seasons. That last rendition of the Legacy Defender, known as the TDCi Puma variant, is the first evidence that passenger compartment comfort was even a consideration.

The combination of a custom oversized radiator and intercooler for the larger engine allows for reduced engine compartment temperatures. This translates to a more consistent ambient cabin temperature. Utilization of the later Land Rover TDCi Puma bulkhead and HVAC system in conjunction with Ford OEM variable speed compressor allows for the proper function of a cooling system for the cabin delivering a marked improvement over the earlier systems. This design includes the first time that a Legacy Defender actually turned OFF the heating system when trying to utilize the cooling system.

heating

In the cooler months, heat delivery has always been a concern. Again, utilizing the TDCi Puma bulkhead and HVAC delivery system, the driver has the ability to deliver a larger volume of warm air to the cabin via multiple speed fan, increased duct work, and vent directional louvers to get the heat where you need it. While not included on every vehicle, we can also include additional options such as heated front and rear windscreens and heated seats as well as fuel-fired supplemental air heating systems for optimal comfort in winter conditions.

cabin noise reduction

Some may consider the droning sound of the drivetrain and wheel road noise as part of the ‘experience’ of owning one of these heritage trucks. When receiving a call - ‘Can’t talk right now, in the Defender’ is a common response.

For those planning to use their truck for daily driving activity or upcoming road trips, our builds have significantly improved on this aspect of the ride.

Sound Deadening: The marketplace for these products is endless and all have a varying level of overall quality and durability. The overwhelming majority of these products are a combination of tar/foil, closed-cell rubber & foam with peel and stick backing. While overall quality/durability varies from product to product, all of these options can provide challenges down the road if you ever want to remove or have water ingress of any kind. Additionally, many of these products are prone to ‘Gassing’, melt, and contain many harsh chemicals that can escape as the product degrades over time. (butyl rubber, such as asphalt, tar, or bitumen)

From years of testing, our preferred method of application is to utilize a dense application of a product called Second Skin Auto. This product is the ‘go-to’ for many that compete in sound/audio competitions and have also found use in the fields of manufacturing, aerospace, medical and military application space.

We apply second skin to the exterior of the firewall and the entire underside of the body including wheel wells to provide complete sound deadening coverage of the vehicle where the majority of the exterior noise infiltration occurs. In addition to the significant reduction in cabin noise, additional benefits of full exterior coverage benefits include:

Corrosion resistance

Water ingress

Climate control (Heat Deflection)

Ease of vehicle cleaning

Future interior modifications

engine mounts

Current in-market Defenders are built with a ladder frame and bolt-mounted body. Mounts utilized to cradle the engine are a dense dual-posted rubber blocks designed to dampen engine deflection and vibration when under load. What we’ve found is that a large amount of engine vibration still carries through the chassis and mounted body leading to significant cabin noise.

The Cummins R2.8 motor provides a much better solution by utilizing modern common rail high-pressure computer-controlled fueling systems which make a substantial reduction in overall engine vibration. In addition, We have recently changed the game with the employment of proprietary hydraulic engine mount system specifically adapted to the Land Rover OEM Chassis and Crate Cummins 2.8 engine without degrading the chassis integrity stemming from cutting & welding new mounts. The end result is a dramatic improvement in overall vibration and cabin noise.

accessories and options

Each build will be provided with our standardized build sheet for what we consider to be the ideal heritage vehicle for the North American market. With endless customization options available, we can further tailor your build to be exactly what you are looking for prior to delivery. A thorough build package inclusive of all items will be provided & finalized prior to construction to ensure everybody is on the same page making the entire start-to-finish experience a pleasurable & smooth process. Common items include:

Winch Bumpers / Grille guards

Steps

Rock Sliders

Roof Racks

Roof Baskets

Roll Cages

And many more ...